CIP Cleaning in Place for milk cooling tanks

Cleaning in Place (CIP) is a widely used method for cleaning the interior surfaces of pipes, tanks, equipment, filters, and associated fittings, without disassembly.

Mostly employed and used in industries such as food, beverage, dairy, pharmaceutical, and cosmetics industry. CIP (Cleaning in Place) ensures equipment is cleaned efficiently while maintaining hygiene standards. It is a key practice in industries where maintaining a high level of cleanliness is essential for product safety, quality, and compliance with regulatory requirements.

CIP is a method that circulates cleaning solutions through the system at certain conditions (temperature, flow rate, concentration) to remove residues, biofilms, and contaminants. Unlike manual cleaning, where equipment has to be taken apart, CIP allows for cleaning in a closed system. This not only saves time but also minimizes the risk of contamination

- This automated process involves circulating cleaning solutions through pipes, tanks, and other machinery to remove contaminants like residues and biofilms, ensuring hygiene and safety.

- CIP typically follows five stages: pre-rinse, detergent wash, intermediate rinse, sanitization, and final rinse.

- Offers several advantages, including saving time and labor, reducing production downtime, and ensuring consistent cleaning.

- However, effective CIP requires careful system design, resource management, and regular monitoring.

- Advances such as automated control systems and real-time monitoring have improved their efficiency, making it an essential practice for maintaining hygiene and compliance with regulatory standards in industries where cleanliness is paramount.

Components of CIP

A typical CIP (Cleaning in Place) system includes several components such as: Tanks, Pumps, Exchanger Heater, Valves, sensors and Piping.

CIP TANKS

The size and number of tanks in your CIP system is determined by the size and complexity of required cleaning. Individual tanks may be used for freshwater, caustic solution, acid solution, reusable washes or rinses, rinse recovery or sanitizer. Tank design depends primarily on the industry, but the materials of construction are commonly austenitic stainless steels such as AISI 304,316 or 316L. Using 304 stainless steel for some food, dairy, beverage, and brewery CIP tank applications are acceptable, but most quality CIP system manufacturers feature 316/316L as the standard material for all wet components, including tanks.

Single Tank System

Ideal for small jobs with easily cleaned soil. Good for special use systems that are infrequently used. Ideal for applications on remote equipment that make service from a large, centralized system impractical. Often preferred for avoiding allergens and cross contamination issues since each cycle is dumped to the drain after a single pass. Requires less space and can easily be cart-mounted for mobility.

Double Tank System

Typically, one tank is for water (for rinse or final rinse) and one for caustic wash solution. It can easily be cart-mounted for mobility.

Tripple Tank System

Allows for many more cleaning options than smaller systems. Water/caustic/acid: Common for many cleaning applications. Allows pre-fill and pre-heat of all solutions, which reduces cleaning time. Caustic and acid washes can be returned and re-used, depending on the amount of soil.

Few CIP (Cleaning in Place) systems require more than four tanks, but additional tanks can be added to any system as necessary to provide nearly unlimited versatility and convenience to the CIP cleaning process. Depending on the type of cleaning needed, each tank must be fitted with all necessary inlet and outlet valves as well as any instrumentation required to monitor volume, temperature, and chemical concentrations.

HEAT EXCHANGER

Temperature is one of the four basic TACT principles essential to the cleaning process, so choosing the right heating source for your CIP system is an important decision. Elevating the temperature of your cleaning solutions will increase their soil-removing efficiency, which in turn will reduce your cleaning time and chemical costs. Each CIP heating system has its own advantages. When choosing, consider the available plant resources.

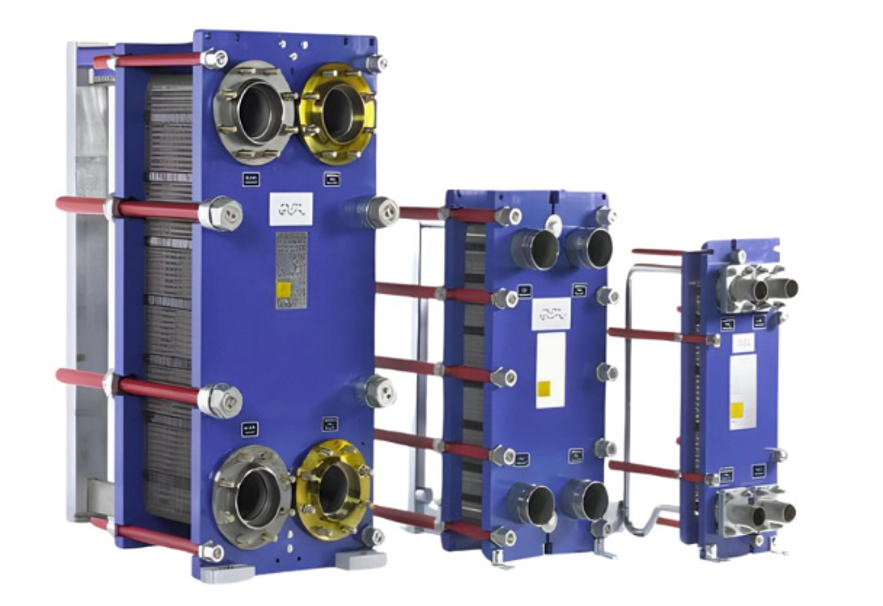

A. Plate & Frame Heat Exchanger

These units are highly efficient and typically have a small footprint allowing a more compact design of the CIP system. Additionally, they have a relatively low steam load requirement, making them a desirable choice for CIP systems.

B. Shell & Tube Heat Exchanger

A simple, low-maintenance in-line heating option. While these units are widely used in the food, dairy, and beverage markets, they are typically found in pharmaceutical applications where complete drainability is required.

C. Direct Steam injection

These units inject precise amounts of steam directly into the cleaning solution as it is being pumped to the process.

D. Electric Heater

Although sometimes slower and potentially more costly to operate than other options, electric heaters can be a prudent choice if other heating options are unavailable.

CIP PUMPS

CIP systems rely on pumps to provide the proper flow and pressure of CIP solutions to the process areas.

Process engineers take various factors into consideration such as length of CIP circuits and types of process equipment to be cleaned to properly size and specify CIP supply pumps.

In addition to the supply pumps on the CIP system, other pumps are required to provide effective CIP within the facility. These pumps can include return pumps, chemical addition pumps, and sometimes CIP boost pumps.

CIP VALVES

They “control the traffic” in a system. They can operate manually or automatically, but manual valves require operator intervention for each step of the cleaning cycle. Several different valves can be used depending on industry, application and amount of automation needed. Your CIP designer may choose from seat, butterfly, or diaphragm valves. 4A. Butterfly Valves A butterfly valve is one of the most common valves for sanitary applications because it lacks internal cavities or voids. Internal cavities promote product buildup, which will result in bacterial contamination. The absence of these cavities in a butterfly valve allows you to avoid contamination, making it a good sanitary valve option.

Single & Double Seated Valves

Single-seated and mix-proof (double-seated) valves are another good sanitary option. These are linear plug-style valves with canister-style cylindrical actuators. Unlike butterfly valves, the plug design eliminates the disc in the flow path. Again, this helps to avoid contamination. The actuators are easier to clean than an industrial style rack and-pinion actuator. Think of a food plant doing a wash down of equipment. Mix-proof valves can also run 2 products (or one product and a CIP cleaning solution) simultaneously, functioning as 2 separate valves. These dual-acting seats avoid spillage and cross contamination.

Diaphragm Valves

For pharmaceutical sanitary applications, a diaphragm valve is a great option. Since there is nothing in the flow path, it can be easily sanitized and sterilized. It is also more cost-effective than a single-seated valve. For extreme applications, a Zero Dead Leg (ZDL) diaphragm valve can be completely drained to avoid trapped media.

CIP SENSORS

Monitor parameters such as temperature, pressure, and concentration.

CIP PIPING & SPRAYS

Deliver the cleaning agents to all surfaces that need cleaning.

Types of CIP (Cleaning in Place) Process

1. Pre-Rinse

The pre-rinse is a very important step in the CIP process because a well-monitored and well-executed pre-rinse makes the rest of the wash cycle predictable and repeatable.

The pre-rinse cycle:

Wets the interior surface of the lines and tanks Removes most of the remaining residue Dissolves sugars and partially melts fats Provides a non-chemical pressure test of the CIP Cleaning in Place flow path Meeting the cleaning requirements during the pre-rinse step is crucial for ensuring the effectiveness of the subsequent cleaning stages. Use potable plant water, de-ionized water (DI), water that has been processed through reverse osmosis (RO), or re-use the final rinse solution from the previous cleaning sequence. A Turbidity Sensor may be used to verify that the pre-rinse effectively removes all solids.

2. Caustic Wash (60 -85 0 C)

Caustic washes soften fats, making them easier to remove. Also known as caustic soda, sodium hydroxide or NaOH, the alkali used in caustic washes have a very high pH in a concentration range of 0.52.0%. Concentrations as high as 4% may be used for highly soiled surfaces. Caustic is typically used as the main detergent in most CIP wash cycles. The use of appropriate cleaning chemicals, such as caustic soda, is essential for breaking down and removing residues effectively. A non-foaming formulation can help reduce pump cavitation and increase efficiency. It will also prevent tanks from overfilling with foam when the system starts to recirculate.

3. Intermediate Rinse

Intermediate Rinse Flushes out the cleaning chemicals and dissolved contaminants using water.

4. Final Rinse

Removes any remaining traces of cleaning agents to ensure the equipment is ready for production.

5. Sanitization Rinse

Use of chemical disinfectants or high temperature water to kill any remaining microorganisms.

ACTIVE INGREDIENT IN A SANIZATION RINSE

The active ingredient in a sanitizing rinse is CHLORINE (BLEACH), which is: Relatively inexpensive to use. Very effective as a sanitizing rinse for soils that are prone to bacterial growth such as dairy products. Potentially harmful to stainless steel, causing staining, corrosion and pitting. In recent years more sanitation managers have turned away from bleach-based sanitizers in favor of peracetic acid (PAA), a combination of hydrogen peroxide and acetic acid.

The PAA Solution

It is a strong disinfectant even at low temperatures. Rinses away while leaving little or no chlorine residue to corrode stainless steel. It is effective against all microorganisms including spoilage organisms, pathogens and bacterial spores. It has also proven to be more eco-friendly in the wastewater stream. It has a strong, pungent odor so it should only be used in well-ventilated areas.

7 STEPS OF CIP PROCESS

- Pre-Rinse

- Caustic Wash

- Acid Wash

- Intermediate Wash

- Final Wash

- Sanitization Rinse

- Air Blow

Although the CIP Process Steps are common, the combination of these steps varies with the nature of the processing line. Depending upon the requirements of the cleaning process, these optional CIP process steps can be also employed in the CIP system: Push Out (The Step before Pre-rinse to achieve Increased Product Recovery and Better Cleaning) Acid Wash (To Neutralize the Alkali Effect of Caustic Wash) Air Blow (To Remove any Remaining Moisture)

Importance of CIP in the Food Industry

MICROBIAL CONTROL

CIP reduces the risk of microbial contamination by thoroughly cleaning surfaces and equipment, thus preventing spoilage and foodborne illnesses.

CONSISTENT CLEANING

Automated CIP systems provide consistent results, ensuring that every cleaning cycle achieves the same level of cleanliness.

COMPLIANCE WITH REGULATORY STANDARDS

CIP helps industries meet hygiene standards set by regulatory bodies such as the FDA, USDA, and ISO, ensuring that products are safe for consumption.

Benefits of CIP

Time & Labour Efficiency

As CIP is automated, it significantly reduces the time and manpower needed compared to manual cleaning.

Minimized Downtime

Quick cleaning cycles result in reduced production downtime, maximizing equipment utilization.

Resource Savings

By reusing water and cleaning agents, modern CIP systems optimize resource usage, making the process more sustainable and cost-effective.

Improved Safety

CIP reduces the risk of contamination and human exposure to chemicals, making it safer for employees.

Challenges & Considerations

While CIP systems offer numerous benefits, there are several challenges that companies must address:

System Design

The equipment must be designed for effective CIP, ensuring all surfaces, especially in dead zones or hardto-reach areas, receive adequate cleaning.

Energy & Water Consumption

CIP can be resource-intensive, requiring large amounts of water and energy. Companies are now adopting technologies such as reclaim systems and more efficient pumps to reduce the environmental footprint.

Chemical Management

Careful selection and handling of cleaning chemicals are crucial. The wrong chemical concentration or incorrect use can lead to ineffective cleaning or damage to equipment.

Validation & Monitoring

CIP systems must be regularly validated and monitored to ensure that cleaning is effective. This includes testing for residual soil, microbial presence, and chemical concentrations.

Advances in CIP

In recent years, CIP technology has evolved to become more efficient and environmentally friendly. Some of the innovations include:

Automated Control System

Modern CIP systems are equipped with programmable logic controllers (PLCs) that automate the cleaning process, ensuring optimal use of chemicals, water, and time.

Single Use CIP System

Designed for smaller facilities, these systems eliminate the need for multiple tanks and pumps, simplifying the cleaning process while saving space.

Water & Chemical Recovery System

These systems capture and reuse cleaning solutions and rinse water, reducing overall resource consumption.

Realtime Monitoring

Sensors and smart technologies are used to monitor cleaning effectiveness in real-time, providing data on flow rates, temperatures, and chemical concentrations.

THE BOTTOM LINE

Cleaning-in-Place (CIP) is a vital process in industries requiring strict hygiene standards, such as food and beverage production. Its automated nature ensures that equipment is cleaned consistently, safely, and efficiently, helping companies maintain product quality and comply with regulatory requirements. While CIP offers numerous advantages, optimizing its design and operation is essential for maximizing resource efficiency and achieving the best possible cleaning outcomes. As technology advances, CIP systems will continue to evolve, becoming more sustainable and responsive to industry needs. By adopting the latest innovations in CIP, industries can ensure both operational excellence and compliance with stringent hygiene standards.